Cellular Concrete is the perfect solution for your next project.

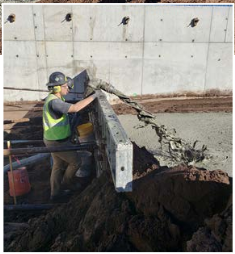

A custom-crafted mixture of cement, water & preformed foam, cellular concrete is capable of being pumped in up to 20' lifts and pumped thousands of feet in a single pour. It can be accurately mixed to a wide range of densities and pumped into any void.

Our unique mixing process allows us to hit very tight margins at any density from 20 to 110 pcf. Plus, our patent-pending equipment pumps at rates up to 250 yd3/hr for thousands of feet, assuring your project is completed quickly, and to your exact specifications.

We are CellFill - an innovative cellular concrete manufacturer and producer centrally located in Grove, OK. All of our proprietary equipment is designed and built in-house, and our centralized Oklahoma location allows us easier travel than most. To date, we've worked in 18 states including Arkansas, Florida, Kentucky, Louisiana, Missouri, Minnesota, Nebraska, Oklahoma, Tennessee, and Texas. Are you next?

What's so great about cellular concrete? Everything!

- Less expensive than traditional grout, CLSM, flowable fill, and lightweight structural concrete.

- Reduces traffic impact and construction time

- Our full-service installation allows contractors to free up laborers

- Self-leveling

- Provides significantly better bearing strength than soil, and drains better than aggregate or sand

- More complete curing equals higher insulating powers

- Provides 100% compaction to fill spaces entirely with almost no shrinkage

- Low water absorption and permeability decreases hydrostatic pressure on walls

- Computerized on-site batching eliminates material inconsistencies and offers real-time batch information

- Does NOT require being pumped under high pressure

- Material is non-HAZMAT and does not provide a food source for harmful mold growth

- Excellent modern green material with a relatively low carbon footprint

- Streamlined approach and turnkey operation of CellFill averages a 20-50% REDUCTION in cost over traditional fill methods

CellFill℠ Process

Our strategy is simple...let us do one job for you and you determine if the cost savings and end product are above and beyond your expectations!

CellFill℠ Applications

CellFill's mobility and high production rate make cellular concrete an ideal material for many applications such as abandoned water and sewer pipes, corrugated metal pipe backfill, mine shaft, and large hole capping, erosion control, bridge backfill behind abutments, and more!

The CellFill Difference

Quality assurance

Our proprietary equipment produces densities from 20-80 pcf with remarkably tight margins. We take samples on every job, and our live onboard computer system lets us monitor the stats of each job in real-time.

Unmatched Pump speed

Material is placed at high rates and high daily volumes (up to 150 cu yd/hour). This reduces the associated costs in traffic control, supervision, dewatering and any other support service that may be reduced by completing the job quicker.

Turn-key solution

We pride ourselves on taking care of everything on our jobs from start to finish including engineering, bidding, installation, and testing. The only thing a contractor needs to do for us is site prep.

Long run lengths

Our cellular concrete can be pumped over long distances without the added cost of a pumper truck, eliminating much of the labor and bulkhead costs associated with placing traditional flowable fill.

Innovative technology

Our patent-pending mix process fully hydrates each cement particle, allows our fills to be more accurate and precise than our competitors. Plus, our onboard computer system shows project stats in real-time, so we can adjust accordingly if necessary.

Cellular structure uniformity

We have the most consistent product on the market in terms of nominal cellular structure. This means the specifications of the cellular concrete we pump is uniform throughout the job, even with subsequent days of pumping.

Applications

The cellular concrete produced by our trucks is an environmentally friendly, cost-effective, and multi-use solution for municipalities and contractors currently working on:

- Abandoned Water & Sewer Pipe

- Fills Bridge Backfill Behind Abutments

- Mine Shaft & Large Hole Capping

- Corrugated Metal Pipe Backfill

- Replacement of Unstable Soil & Erosion Control

Family Owned and Operated in the USA

Centrally located in Grove, OK, CellFill is a family-run business.

Christian values, quality over quantity, and staying on the leading edge of innovation are the driving forces behind every piece of equipment they create. James Diver is a Civil Engineer with a passion for concrete dating back to 1997. Renee Diver is a master marketer and mom. Together they have successfully launched multiple business endeavors in the cellular concrete industry. James and Renee have three daughters and hope someday they will continue on the legacy of their collective entrepreneurial spirit. Until then they abide by the motto that you have to, “Risk It To Get The Biscuit,” and put everything they have into each and every day.

JOBSITE MEETING

SETUP

PUMPING

JOB SIGN OFF & CLEANUP

FOLLOW-UP