PROJECTS

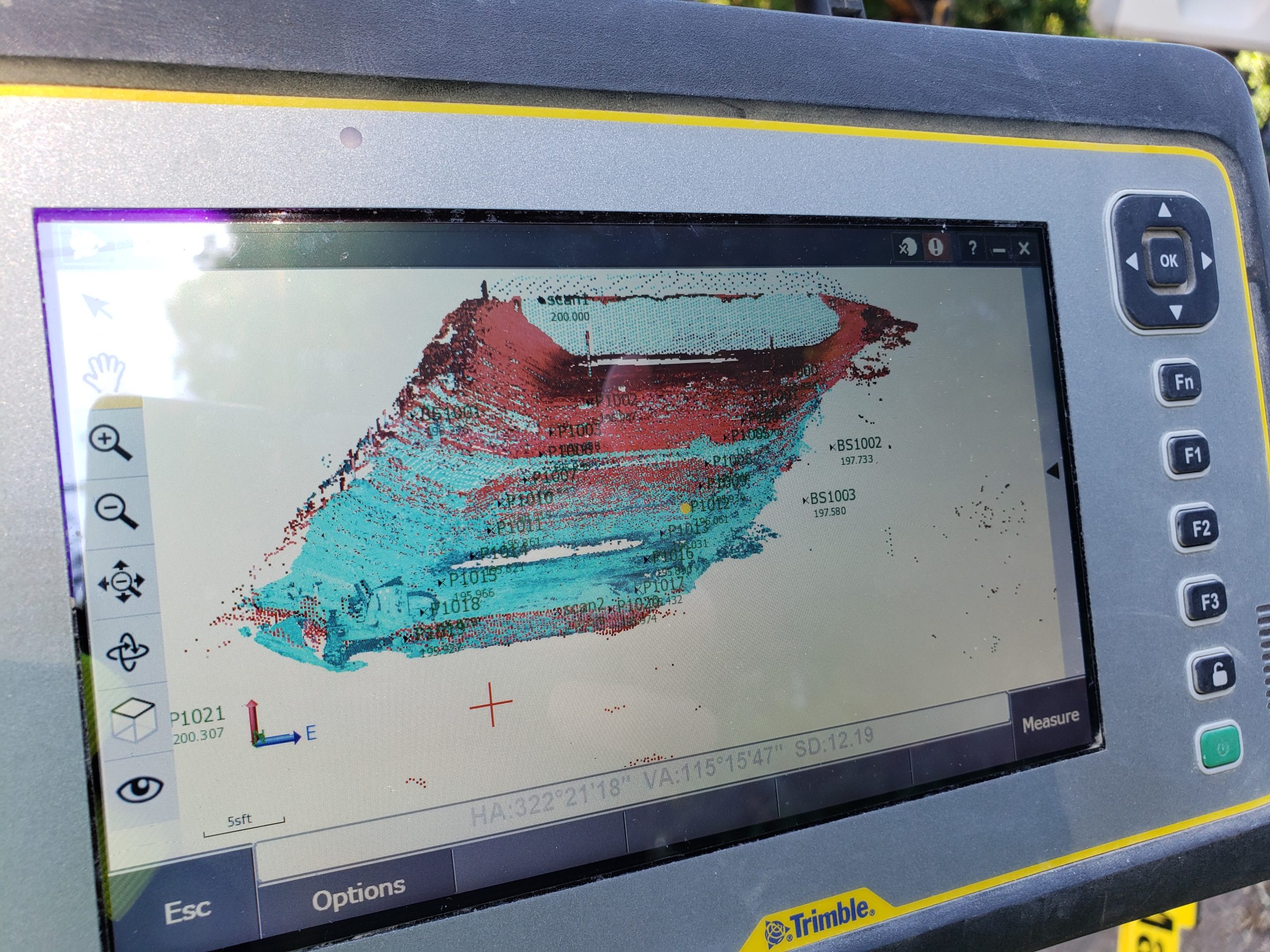

Hubbard Construction – West Lake Eloise Drive

- Winter Haven, FL

Since its initial construction in the 1940s, this roadway had experienced continuous settlement with an estimated total settlement of more than four feet at the worst location. The settlement occurred due to organic sub-soils consisting of peat and muck. Permeable low-density cellular concrete (LDCC) presented a viable option that would decrease the weight placed on the underlying soils while also facilitating the elevation of the roadway and addressing the high water table present on both sides of the roadway.

CellFill installed 24 helical anchor piers to prevent upheaval of the material before placement of new roadway. The crew then pumped three-foot thick lifts over the course of two days for a total of 671 cubic yards of permeable fill.

SiteMix – McLeod Road Transfer Station Replacement

- Orlando, FL

LDCC was chosen as a fill material on this project to decrease time of installation and bear all of the weight of the tipping floor and structure. The six-person crew installed 6,600 cubic yards of non-permeable LDCC at an average rate of 175 cubic yards per hour. The LDCC was placed using four-foot lifts at a maximum heigh of eight feet. The use of cellular concrete not only provides greater stability and compressive strength, it also provides a significant reduction in labor and shortens the construction timetable when compared to more traditional materials.

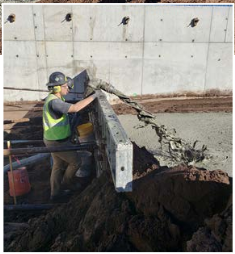

Crossland Construction – Aquarium Sub-Grade Backfill

- Branson, MO

Crossland Construction chose to utilize cellular concrete for the sub-grade backfill of the new Branson Aquarium due to the ease and speed versus using traditional #57 stone. Cellular concrete was chosen because the #57 stone was going to have to be hauled in and lifted via clamshell over the CMU wall that had already been constructed.

CellFill installed a total of 4,380 cubic yards of cellular concrete around the underground pipe network for the aquarium’s utilities. The crew accomplished this in nine working days. A portion of the cellular concrete was pumped successfully in below-freezing temperatures, allowing the project to continue with no delay.

Brandenburg – Tyrone Power Plant

- Lawrenceburg, KY

CellFill was subcontracted by Brandenburg for the abandonment of the Tyrone Power Station – a coal-fired power plant. Cellular concrete was used in lieu of traditional CLSM to fill in the basement of the structure which had an overall depth of 34 feet. This was completed over the course of twelve working days and a total of 16,106 cubic yards were placed.

The CellFill team was able to accomplish this in a short period of time due to utilizing larger lift heights, in excess of 11-feet. The stability of the cellular concrete produced through CellFill’s proprietary equipment allowed for the larger lift heights which resulted in accelerated construction time. The foam generation and the highly efficient mixing process of the neat slurry create a stable product which has been proven time and time again.

Driver Pipeline – DT3 Abandonment

- Irving, TX

The use of low-density cellular concrete (LDCC) ensures the pipe’s long-term stability and minimizes the potential for expensive damage to surrounding areas. The two most essential elements of this project were ensuring quality control of the LDCC throughout the mixing and application process and selecting an LDCC product that would facilitate long-distance pumping into this 22,953 linear foot pipeline. Flexibility and speed were non-negotiable necessities.

Given these considerations, the CellFill team chose to use AERLITE-iX a non-pervious LDCC manufactured by Aerix Industries. Over the space of ten days, the crew pumped 2,676 cubic yards of LDCC into the pipeline in eight segments, the longest of which was 5,381 linear feet.

Irving, TX – NTC Abandoned Waterline Fill

- February 2017: Irving, TX

- CellFill℠ As Fill For Abandoned Waterline

Our largest project to date! CellFill℠ pumped 5921.24 CY of cellular concrete into over 12,000 linear ft of 48” diameter abandoned waterline in Irving, TX. This job paralleled Irving’s busy Hwy 183 and warranted constant site supervision and time management/coordination with North Texas Contracting and the highway authority.

This project included 18 different pumping locations and was still completed in 8 days time.

Branson, MO – Spirit of 76 Project

- September 2016 to Present: Branson, MO

- CellFill℠ As Protective Encasement for Underground Utilities

CellFill℠ is part of a 3-5 year revitalization project in the heart of Branson’s famed strip, Highway 76. The City of Branson is burying its utilities along its 5 mile strip as part of the “Spirit of 76” beautification project. The new utility duct banks include 12” waterline, electric, cable, phone and fiber cables. Due to how close the conduit is placed together, you could not properly compact with traditional granular backfill, and settlement issues were a big concern. CellFill’s cellular concrete is fully bedding the conduit and providing 100% compaction. It’s a win-win for everyone!

Lowell, AR Storm Sewer Pipe Fill

- December 2016: Lowell, AR

- CellFill℠ As Fill For Abandoned Storm Sewer Pipe

5092 CY of cellular concrete was used to fill this 48” abandoned storm sewer pipe for the City of Lowell, AR. We cranked it up to produce at rates averaging 135 CY per hour. It was fun working on this project with Nabholz Construction, despite the COLD December wind!

Colcord, OK Drainage Layer Under Roadway

- March 2016: Colcord, OK

- CellFill℠ As Drainage Layer Under County Road

CellFill℠ traveled to Colcord, OK, to place 20 cu yds of cellular concrete as a drainage layer under 350’ of Delaware County concrete roadway. Big floods washed out the rock at varying depths underneath the road, so CellFill℠ was a perfect solution for filling these voids completely.

The entire project was finished in 4 hours, from set up to pumping to clean up!

Adair, OK Abandoned Diesel Line Fill

- February 2016: Adair, OK

- Abandoned Diesel Line Fill for Explorer Pipeline Company

Explorer Pipeline Company hired CellFill℠ to pump cellular concrete into 3200’ of 2’ diameter (372 cu yds total) of abandoned diesel pipeline. The location of this job (in the middle of a pasture), and the distance from our CC150 rig to the pipe (300’) make this job a great example of the versatility of CellFill’s℠ mobile unit and pumping capabilities. Our client couldn’t be happier with the results!